Image credit: Pexels

American manufacturing, once the pride of the global industrial landscape, saw a steep decline in the late 20th century. Offshoring and automation stripped factory floors of workers and even eroded the entire domestic industrial landscape. However, in a surprising twist, certain domestic sectors are now writing a new chapter. This time, they are rebuilding themselves from the ground up. Small producers in watches, bikes, and apparel are leading a focused resurgence in American manufacturing. Their growth is redefining the whole concept of making things in America.

Why Are Niche American Brands Reshoring?

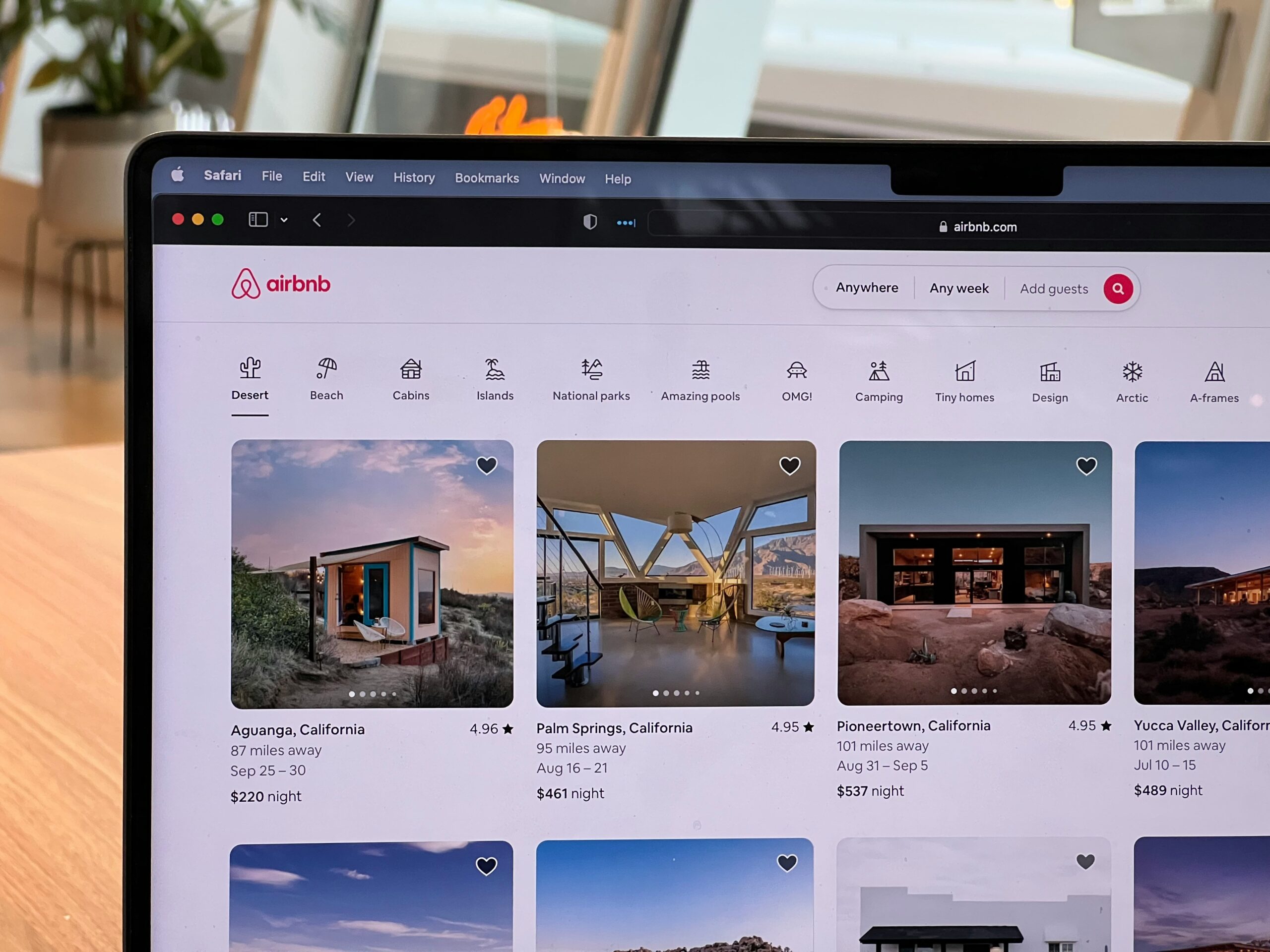

Unlike large manufacturers, these small companies aren’t chasing volume; they’re responding to economic shifts and rapidly evolving consumer preferences. Tariffs have made overseas production less cost-effective, while global supply chain disruptions have exposed the vulnerabilities of offshoring. At the same time, more consumers are prioritizing transparency and the place of origin. The “Made in USA” label now carries renewed weight for consumers, encouraging businesses to invest more in their production homes.

This shift in consumer behavior is proving favorable for niche producers who offer unique, high-quality goods. By capitalizing on evolving consumer demands and avoiding overseas uncertainty, these companies are finding new ways to make domestic manufacturing viable despite the odds.

The Cost of Staying Local

Reshoring has come with a set of significant obstacles. Labor shortages are especially acute in specialized trades like watchmaking and machining, which are fields where experience is hard-won and aging out. Infrastructure is another gap, as the U.S. manufacturing landscape lacks micro-assembly facilities that are crucial for industries that rely on intricate component integration.

The cost factor cannot be ignored here. Manufacturing domestically can be three to five times more expensive than overseas alternatives. This is forcing companies to either charge more or find innovative efficiencies.

Solving for the Future

While navigating through these challenges, niche brands are turning to creative solutions. Some are forming training partnerships, particularly with veteran-focused programs, to build a pipeline of skilled workers. Others are embracing open-door transparency to forge stronger connections with customers and highlight the value of locally made products.

A standout example here is the Vortic Watch Co. in Fort Collins. The company has scaled up domestic production of modern watches by investing in both equipment and people. “We’re asking people to vote with their wallet. If you care about where your watch is made, then you buy one of our Colorado watches,” says founder R.T. Custer.

These businesses aren’t aiming to match the output of global manufacturers. Instead, they’re building credibility and customer loyalty by offering something global supply chains can’t: authenticity, traceability, and trust.

A Values-Based Future for the Manufacturing Sector

The U.S. may never return to its former mass-production glory, but perhaps it doesn’t need to. In place of scale, niche industries are offering sustainability, resilience, and values-driven operations.

From precision watches to handcrafted bicycles and boutique apparel, the future of American manufacturing may rest not in sheer volume but in a commitment to showcase exclusive craftsmanship, boost local economies, and focus on long-term viability. In the process, these small companies are changing the narrative for American manufacturing in the global industrial landscape.